Introduction

Lithium batteries have been commercialized in various applications for more than 20 years. So why aren’t they ubiquitous in the batteries of UPS in data center? In fact, the reason is that, like all other applications, lithium batteries in UPS applications do not provide a reasonable balance of price, energy density, power, safety and reliability for UPS suppliers. But over the past decade, improvements in lithium ion chemistry and technology have provided A viable solution for UPS suppliers. These improvements are largely driven by the development of the electric car industry.

In the UPS uninterruptible power supply system, the backup battery is the last line of power supply protection of the whole power supply system, but also the focus and difficulty of power supply maintenance work. In the system interruption accidents, the failure caused by the battery takes a large proportion. Therefore, people will be more cautious about the reform of backup battery technology.

Valve controlled lead-acid batteries have been widely used in many industries after decades of development. Similarly, which is also the first choice of UPS in data centers, communications and various computer rooms. However, with the development of information technology, people have higher requirements on the reliability of the power supply system and stronger awareness of realizing green environmental protection. Therefore, it is more urgent to solve many problems existing in valve-controlled lead-acid batteries.

Valve-controlled lead-acid batteries compared with lithium iron phosphate(LFP) batteries

1.Low mass to energy ratio, low volume to energy ratio, large battery weight, big coverage.

2.Low charge and discharge efficiency, about 92%, after a period of use, the charge and discharge efficiency will decrease.

3.Valve controlled lead-acid battery life is short, the design life is 5-8 years, the actual use is mostly 3-5 years.

4.The operating environment has high requirements on temperature. When the ambient temperature exceeds 25 ° C, the battery life will be halved when the ambient temperature increases by 7 ° C to 10 ° C.

5.Lead is widely used in batteries, which is easy to cause serious pollution to the environment in the process of mining, processing and use.

In order to solve the above problems, the communication industry and some well-known brands of high-power UPS equipped with lithium iron phosphate battery applications are increasing, a new trend in the UPS market is the growing interest in lithium ion batteries for data center and UPS applications. Compared with traditional lead-acid batteries, lithium-ion batteries have longer service life, smaller size and weight, the ability to operate in a wider range of environments, and can be charged and discharged quickly with large current. They have excellent high temperature resistance and can still work normally under the condition of -10℃ ~ +65℃. Total cost of ownership (TCO) is better.

Internal structure and working principle of lithium iron phosphate battery

The internal structure of lithium iron phosphate battery can be divided into plate, separator, electrolyte, shell, safety valve, terminal, etc., as shown in following picture.

On the left is LiFePO4 of olivine structure as the positive electrode of the battery, which is connected with the positive terminal of the battery by aluminum foil. On the right is the battery negative electrode composed of carbon (graphite), which is connected with the negative terminal of the battery by copper foil. In the middle is a membrane, which separates the positive electrode from the negative electrode, but lithium ion Li+ can pass through while electronic e – cannot. Between the top and bottom of the battery are the battery’s electrolytes, which provide a transport medium for the movement of lithium ions.

When the LiFePO4 battery is charged, the external current flows from the negative electrode to the positive electrode, causing the lithium ion Li+ in the positive electrode to escape from the lattice of excessive metal oxides such as lithium iron phosphate, and migrate to the negative electrode through the bridge of liquid electrolyte through the membrane, and embed into the layered structure of the carbon material negative electrode. The volume of the cathode material changes due to the removal of lithium ions, but its skeleton structure remains unchanged.

When the LiFePO4 battery is discharging, the lithium ion Li+ in the negative electrode is released from the carbon material layer, passes through the bridge of liquid electrolyte, migrates through the membrane to the positive electrode, and is embedded in the lattice of the positive electrode material. Accordingly, the current flows from the positive electrode to the negative electrode through the external load.

Lithium iron phosphate material is olivine phosphate type lithium embedded material, crystal structure is stable, not easy to deformation or damage in the process of charge and discharge. Similarly, the repeated insertion and removal of lithium ions will only cause the change of the layer spacing of the anode material, and will not cause the destruction of the crystal structure of the material. Lithium-ion batteries are also known as rocking chair batteries. The crystal structure of lithium iron phosphate is shown in below picture.

Features of lithium iron phosphate batteries

The main technical points of lithium iron phosphate battery are as follows: nominal voltage 3.2V, the general charging current is 0.2-0.5C, the maximum charging current is 1-1.5C, the performance is stable when the charging voltage is below 3.65V; The general discharge current is 0.5-1C, the maximum discharge current is 5-10C, and the discharge cut-off voltage is 2.0V. Charging operating temperature range is 0~55℃, discharge operating temperature range is -20~60℃.

Lithium iron phosphate battery has the following advantages:

1.High output voltage: working voltage range of lithium iron phosphate battery: 2.5 ~ 3.6V, platform about 3.2V;

2.Strong safety: lithium iron phosphate anode material has good electrochemical performance, the charging and discharging platform is very stable, the structure is stable in the process of charging and discharging. Even if the battery is damaged inside or outside, the battery does not burn, does not explode, good safety;

3.Good high temperature performance: the internal temperature is as high as 95℃ when the external temperature is 65℃, and the temperature can reach 160℃ at the end of the battery discharge. The structure of the battery is safe and intact;

4.High efficiency output: standard discharge 0.5 ~ 1C, continuous high current discharge up to 3C, instantaneous pulse discharge (10S) up to 10C;

5.High cycle life: after 3000 cycles, its discharge capacity is still more than 80%;

6.Easy to use: fast charging;

7.Environmental protection: the whole production process is clean and non-toxic. All ingredients are non-toxic.

8.non-rare resources: lithium iron phosphate battery adopts phosphoric acid source, lithium source and iron source as materials, without strategic resources and rare resources.

Comparison of properties of lithium iron phosphate with other lithium ions

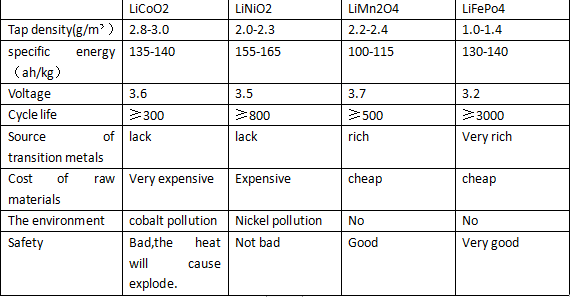

The performance comparison of lithium cobaltate (LiCoO2), lithium nickel (LiNiO2), lithium manganese (LiMn2O4), lithium iron phosphate (LiFePO4) and other cathode materials is shown in the below table.

Performance comparison of lithium iron phosphate and valve-controlled lead-acid batteries (See below table)

Application of lithium iron phosphate battery in UPS power supply system

According to the characteristics of lithium iron phosphate battery, when setting UPS power supply system, it is only necessary to adjust the charging voltage of UPS to the battery pack to the voltage required by lithium battery. Because the performance of lithium battery is not easy to change due to its BMS equalization protection function, even if it is charged for a long time.

Intelligent intermittent charging and discharging management includes the following two steps, as shown in picture: constant current, constant voltage charge phase: battery charging circuit according to the voltage of each cell charging control, control of battery cell and pack charging voltage meet charge limit voltage requirements (charge limit voltage: 3.7 V battery cell,), until all the batteries are fully charged;

Intermittent replenishment stage: Battery pack after complete the whole process of constant current, constant voltage, the battery pack is controlled by BMS into open circuit in static state, until the capacity to reduce the initial capacity of the battery limit voltage SOC (where X values between 75 ~ 95), controlled by the BMS battery added back into the electrical state, adds electricity way also follow the constant current, constant voltage charge way; The BMS should be able to control the battery pack to discharge without delay in the event of an AC power failure in the open circuit static state (see below picture).

T1 and T3 are charging processes, T1 is constant current-constant voltage charging stage, T3 is intermittent supplementary charge stage. T2 is the battery pack open-circuit static stage; T4 indicates the battery string discharge process.

Application scheme and investment comparison of UPS with lithium iron phosphate and sealed valve-controlled battery pack

Example – UPS battery capacity configuration in a data center:

The ambient temperature of the air conditioner in the battery room is set to 25 ° c, the UPS system capacity is 200kVA(396V/425A), and the battery discharge time is 0.5 hour. After calculation, it is necessary to configure a pack of 396V/500Ah lead-acid battery, or a pack of 396V/200Ah LFP battery. Considering the same bearing conditions of the equipment room, the floor area of the latter is 28% of the former, and the weight of the latter is 16% of the former. The large current discharge characteristics of lithium iron phosphate battery can reduce the room area and load bearing requirements, and facilitate the realization of decentralized power supply.

Lithium battery adopts three-layer battery management system, from the battery cell to the battery cabinet, battery cabinet parallel system, layer by layer to ensure the reliability of lithium battery. The CeramiX can design and choose the special lithium management system provides functions such as battery voltage and temperature detection, current management, charge and discharge detection, SOC and SOH management, alarm management, and report analysis. Realize timely identification, early warning and active isolation of battery failure.

Second, lithium has the unique active current sharing technology in the industry, which supports the mixed use of new and old battery cabinets. The parallel circulation of lithium cabinets can be controlled below 2%, significantly reducing Capex.

In terms of hardware design, the lithium battery cabinet is equipped with circuit breakers, and the battery management module is equipped with fuses and relays to ensure fast action and protect the battery in case of failure.

In the aspect of operation and maintenance management, the lithium management system can be integrated into the UPS management system, and the battery management and UPS management system are a complete system. The lithium management system uploads battery information to the UPS system, and works with CeramiX UPS and network management system to achieve intelligent battery management, reduce detection frequency, and ensure that the running status of the lithium battery can be checked, managed, and controllable at any time.