Background introduction:

With the development of the economy and the improvement of people’s living standards, people gradually realize the importance of sustainable development. New energy power generation technology has always been regarded as the way to solve the energy crisis. However, at present, the electric energy generated by the new energy technology does not match the parameters of the power grid, so the problems of normal grid connection or low grid connection ability always exist. The emergence of energy storage systems has played a positive role in solving the problems of new energy generation and grid connection. Further promote the popularization and promotion of new energy power generation application solutions, effectively solve the problem of centralized deployment of distributed energy, and achieve a qualitative leap in the ability of new energy power generation to connect to the grid.

Large-capacity battery energy storage systems have been used in power systems for more than 20 years. In the early days, it was mainly used for frequency regulation, hot backup, voltage regulation, and isolated grid backup. The application of battery energy storage systems in new energy grid connections is also carried out around the world. In the late 1990s, a battery energy storage system with a capacity of 1.2MWh was installed in the Hern 1MW photovoltaic power station and the Bocholt 2MW wind farm in Germany, which realized peak regulation, uninterrupted power supply, and improved power quality. Since 2003, Japan has installed a 6MW/6MWh all-vanadium flow battery (VRB) energy storage system in a 30.6MW wind farm in Hokkaido to smooth output power fluctuations. In 2009, the UK EDF grid deployed a 600kW/200kWh lithium-ion battery energy storage system in the eastern 11KV distribution network STATCOM for power flow and voltage control, and active and reactive power control. In the future, various energy storage cases will be born one after another.

Generally speaking, the application purpose of the energy storage power station (system) in the power grid mainly considers “load regulation, cooperation with new energy access, compensation for line loss, power compensation, improvement of power quality, isolation of power grid operation, and peak regulation”. Great functional applications. For example, peak shaving and valley filling can improve the operation curve of the grid. In simple terms, an energy storage power station is like an energy storage bank. Peak use. This reduces the waste of electric energy; in addition, the energy storage power station can reduce line losses, increase the service life of lines and equipment; optimize the power supply layout of the system, and improve the quality of the power supply. The green advantages of energy storage power stations are mainly reflected in scientific safety. Short construction period; green environmental protection, promotion of environmental friendliness; intensive land use, reduce resource consumption, etc.

Typical structure of energy storage on the power generation side:

Affected by the external environment and other factors, the output power of the new energy power generation system fluctuates randomly, and the switching of loads in the system is also uncertain. The main function of the energy storage device is to supplement the power shortage of the system, make the system run in the process of dynamic balance, ensure the stable operation of the system, and restrain the voltage fluctuation of the system. To maintain the stability of the system bus voltage, the energy storage unit must achieve the balance between the power generated and the power consumed by the load through the function of peak shaving and valley filling. Similarly, the stability of the system output voltage is the external manifestation of the balance of the system input and output power. Therefore, the power balance and voltage stability of the system are combined, and the control of the energy storage system is realized through the algorithm of tracking the DC side voltage through the charging and discharging of the energy storage unit.

The role of energy storage on the power generation side:

For traditional thermal power units, energy storage is applied to the power generation side to improve unit efficiency, assist dynamic operation, and replace or delay new units. On the other hand, charging and discharging the energy storage system according to the current generation curve and the real-time instructions of the dispatch center can adjust the total output of the generator set so that the generator set can operate under the condition of close to the rated power, which enhances the overall performance of the power plant. Peak shaving capability. In addition, the generator set charges the energy storage system during the low power consumption period, which can satisfy the efficient and rapid discharge to the load during the peak power consumption period, and ensure the stable operation of the power grid. For new energy sources such as wind power and photovoltaic power generation, as an emerging technology, energy storage can not only solve the problems of volatility and intermittency of new energy power generation but also improve the flexibility of the power grid and the ability to absorb new energy locally. The role of energy storage in wind farms is mainly to increase wind power regulation capacity, track planned output, and smooth wind power output. The main functions of energy storage in centralized grid-connected photovoltaic power plants are power peak regulation, power quality control, and system stability.

Selection principle of the energy storage battery:

As an access port on the power generation side, to achieve peak shaving, load compensation, and energy storage power stations to improve power quality applications, energy storage batteries are a very important component and must meet the following requirements:

It is easy to realize multi-mode combination to meet higher working voltage and larger working current;

The battery capacity and performance can be detected and diagnosed so that the control system can realize the dispatching control of the power station load under the condition of predicting the battery capacity and performance;

High safety and reliability: Under normal use conditions, the normal service life of the battery is not less than 10 years; in extreme cases, even if a failure occurs, it is within a controlled range, and there should be no explosion, combustion, etc. that endanger the safe operation of the power station. Fault;

It has a good fast response and high-rate charge-discharge capacity, generally requiring 5-10 times the charge-discharge capacity;

High charge-discharge conversion efficiency;

Easy to install and maintain;

Has good environmental adaptability and wide operating temperature range;

In line with the requirements of environmental protection, no damage and pollution to the environment are generated during the production, use, and recycling of batteries;

Helping customers find suitable battery and system solutions is one of CeramiX‘s services.

Comparison of major battery types:

| Sodium-sulfur battery | All vanadium flow battery | Lithium iron phosphate battery | VRLA battery | |

| Existing application scale level | 100kW~34MW | 5kW~6MW | kW~MW | kW~MW |

| Suitable application | Large-scale peak shaving and valley filling, smoothing the fluctuation of renewable energy power generation | Large-scale peak shaving and valley filling, smoothing the fluctuation of renewable energy power generation | Power type or energy type can be selected for a wide range of applications | Large-scale peak shaving and valley filling, smoothing the fluctuation of renewable energy power generation |

| Safety | Do not overcharge; leakage of sodium and sulfur has potential safety hazards | Safe | Individual monitoring is required, and there has been a breakthrough in security performance | Safety is acceptable, but waste lead-acid batteries seriously pollute soil and water sources |

| Energy Density | 100-700 Wh/kg | Super low | 120-150 Wh/kg | 30-50 Wh/kg |

| C-rate | 5-10C | 1.5C | 5-15C | 0.1-1C |

| Conversion efficiency | >95% | >70% | >95% | >80% |

| Life | >2500 | >15000 | >3000 | >300 |

| Focus point | Security, Consistency, Cost | Reliability, Maturity, Cost | Consistency | Consistency, Life |

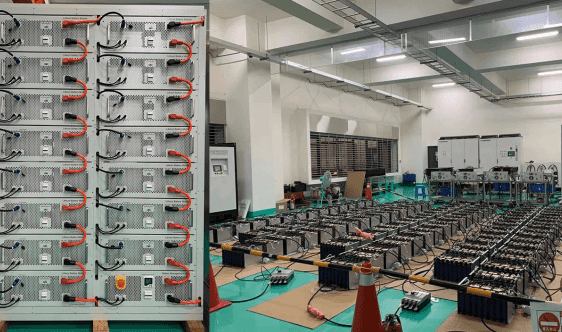

CeramiX can provide the best quality lithium iron phosphate battery supply services and overall system solutions.

Battery management system (BMS) requirements in energy storage systems:

In energy storage power stations, energy storage batteries are often composed of dozens or even hundreds of battery packs. Due to the inconsistency of battery internal resistance, voltage, capacity, and other parameters during the production process and use process of the battery. This difference is manifested in the different voltages or energy differences between the series-connected cells when the battery pack is fully charged or discharged. This situation will lead to partial overcharge, and the cells with too low voltage may be over-discharged during the discharge process, thereby significantly increasing the discreteness of the battery pack, making it easier to overcharge and over-discharge during use, and the overall capacity Dropped sharply, the entire battery pack exhibits the capacity of the worst-performing cell in the pack, ultimately causing the pack to fail prematurely.

Therefore, for lithium iron phosphate battery packs, a balanced protection circuit is necessary. Of course, the battery management system of a lithium battery is not only the balanced protection of the battery but also has more requirements to ensure the stable and reliable operation of the lithium battery energy storage system.

Specific functions of the battery management system (BMS):

- Basic protection functions

Single-cell voltage equalization function: This function is to correct the discreteness of voltage or energy caused by the process difference of the battery cells in the series battery pack, to avoid the change in battery performance caused by overcharge or over-discharge of individual cells. poor or even damaged.

Battery pack protection function: single battery over-voltage, under-voltage, over-temperature alarm, battery-pack over-charge, over-discharge, over-current alarm protection, cut off, etc. - Data collection function

The collected data mainly include: single battery voltage, single battery temperature (the temperature of each battery module), group terminal voltage, charge and discharge current, and the internal resistance of the battery is calculated. - Diagnostic function

The BMS should have the function of analyzing and diagnosing battery performance and can measure battery module voltage, charge and discharge current, temperature, single battery terminal voltage, calculated battery internal resistance, and other parameters in real-time. - Thermal Management

During the charging process of the lithium battery module, a large amount of thermal energy will be generated, which will increase the temperature of the entire battery module. Therefore, the BMS should have the function of thermal management. - Troubleshooting and Fault Tolerance

In case of abnormality, the BMS should give a fault diagnosis alarm signal and send it to the upper control system through the monitoring network. - Battery online capacity evaluation SOC

Based on measuring dynamic internal resistance and true value voltage, using the corresponding relationship between charging characteristics, and discharging characteristics, using a variety of mode segmentation processing methods, mathematical analysis, and diagnosis model are established to measure the remaining power SOC. - Battery State of Health Assessment SOH

The corresponding relationship between the charge and discharge characteristics of the operation curve of the lithium battery is analyzed, and the curve fitting and comparison are carried out to obtain the battery state of health evaluation value SOH, and the evaluation value is corrected according to the operating environment. - Other protection techniques

For battery overvoltage, Undervoltage, overcurrent, and other fault conditions, the circuit is cut off for protection. A fast fuse is generally used in the busbar circuit, and in each battery module, a high-speed power electronic device is used to achieve fast cutting.

Power conversion system (PCS) and its intelligent components:

The power conversion system (PCS) realizes the control of battery charge and discharge to meet the grid connection requirements of the energy storage system. Research the multi-objective converter control strategy. On the one hand, the voltage and current during the charging and discharging process are precisely controlled to ensure the efficient charging and discharging of the battery pack; In addition, under the condition of power grid fault, the coordinated control of multi-energy storage PCS units is studied to realize the safe operation of the local power grid. The intelligent component converts the switch quantity, analog quantity, non-electric quantity, running information, etc. that the PCS needs to upload into the IEC61850 protocol and uploads it to the monitoring system through the Ethernet, and at the same time forwards the mode switching command and the fixed value setting issued by the monitoring system to the PCS.

CeramiX will provide customers with suitable BMS and PCS solutions so that customers can enjoy a high-quality energy storage experience.

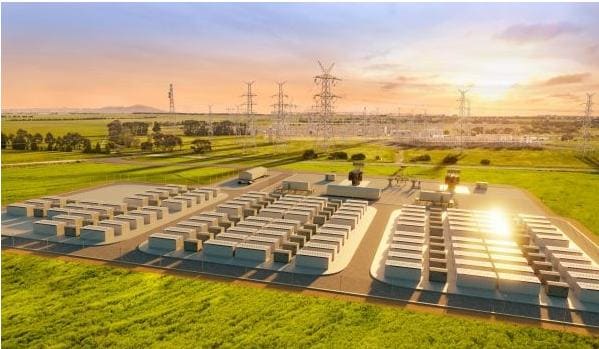

The overall development prospect of energy storage power station (system):

Global energy is in short supply, and the development of emerging energy industries is imperative. However, clean energy such as wind energy and solar energy is greatly affected by the environment, and the power is unstable, which makes the traditional power grid unable to carry it, and a large amount of energy is wasted. One of the main reasons is that the energy storage technology is backward, and the existing energy storage power stations cannot achieve power compensation and cannot meet the demand for power smoothing. It can be said that the development of energy storage power stations has become one of the cores of new energy development.

In addition to photovoltaic power generation systems, energy storage power stations are also widely used on the following occasions:

Factories, enterprises, business centers, etc. with large load fluctuations;

Power stations that need to have a “black start” function;

Wind and tidal power stations with fluctuating power generation quality;

Nuclear power, wind power, and other power generation facilities that need to store energy at night for use during the day;

Areas where the development of small thermal peaking power stations or other high-polluting power stations is restricted due to environmental protection reasons;

Outdoor temporary large load center.

Compared with the existing energy storage technologies such as pumped storage and compressed air energy storage, the energy storage power station with lithium iron phosphate battery as the core energy storage technology has obvious advantages in cost and operating life, outstanding economic benefits, and huge demand, the application prospect is broad. As the global electricity demand increases year by year, the loading gap between the peak and trough of electricity consumption is getting wider and wider. As an emerging technology, lithium iron phosphate battery energy storage power station (system) will bring revolutionary technological updates to the field of grid energy storage, with huge social and economic implications.

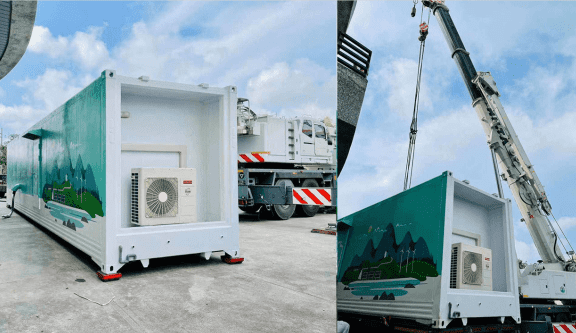

CeramiX has experience in the configuration of various outdoor energy storage systems and will provide customers with optimized battery solutions and module solutions.