Background introduction

Around the 1950s, in the small town of Los Angeles, the number of unnatural deaths exceeded 400 each year. It was finally identified that the pollutants emitted by automobiles caused. Therefore, after years of research and discussion, the United States finally formulated and implemented a global vehicle emission standard in the 1970s. Despite the implementation of increasingly stringent vehicle emission standards, more than 90% of California residents still live in conditions where the air quality does not meet federal standards due to its large population, developed economy, a large number of vehicles, and natural conditions., and therefore the United States will allow California to independently formulate more stringent vehicle emission standards than the United States.

In 1990, the California Air Resource Board (CARB) passed a regulation that any company that sells more than 60,000 cars in California annually must assume the obligation: Sell a certain percentage of zero-pollution cars (only electric cars were zero-pollution at the time) The 1998 period stipulated a ratio of 2%, 5% in 2001, and 10% in 2003. However, due to the immature battery technology, high price, and lack of infrastructure at that time, the implementation of this regulation was suspended in 1996 after being evaluated by third-party experts. But also because of this opportunity, since the mid-1990s, some counties and cities in the three states of California, Florida, and Arizona have regulated their regulations to allow speed-up golf carts, so that the maximum speed is 40 kilometers. per hour. In the spring of 1996, Bombardier Inc., which produces neighborhood electric vehicles, formally applied to the National Highway Traffic Safety Administration to establish a new category of electric vehicles Get four-wheel, zero-emission, low-speed, low-cost neighborhood electric vehicles on the road legally. This is the origin of the development of low-speed electric vehicles.

Although low-speed electric vehicles have been developed for nearly 30 years, due to the low barriers to entry in the low-speed electric vehicle market, there are currently many small and informal enterprises in the market that manufacture low-speed electric vehicles. This part of the product flows into the market, which affects the sales of compliant products. In addition, the mass sales and use of low-speed electric vehicles also increase the complexity of existing road traffic. Low-speed electric vehicles are similar in size to motor vehicles, but they are quite different in terms of driving speed and other indicators. In a complex traffic system, how formulating traffic rules for low-speed electric vehicles is also a practical problem. In addition, the voice for battery upgrades for low-speed electric vehicles is also increasing. One of the representative suggestions is that the existing low-speed electric vehicles with lead-acid batteries should be upgraded to low-speed electric vehicles with lithium batteries to meet market demand. After the upgrade, the technical threshold of low-speed electric vehicle battery manufacturing will be raised, and with proper management, the grade and safety of the product will be greatly improved. Although the cost of low-speed electric vehicles will increase after changing to lithium batteries, the reform of the battery system can better promote the integration of the low-speed electric vehicle market into the trend of new energy development, and develop towards environmental protection and clean energy. The development prospect of low-speed electric vehicles must be “low-speed, low-cost, not low-end”!

Definition and classification of low-speed electric vehicles

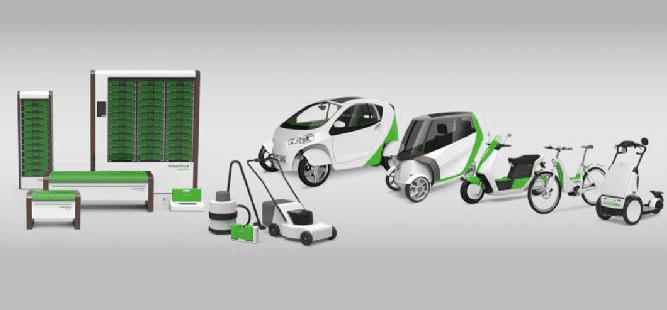

Broadly speaking, low-speed electric vehicles include electric bicycles, electric motorcycles, electric tricycles, and low-speed electric vehicles. The low-speed electric vehicle refers to a simple four-wheeled pure electric vehicle with a speed of less than 70km/h, and its shape, structure, and performance are similar to those of fuel vehicles. Four-wheeled low-speed electric vehicles are also known as low-speed electric vehicles, small electric vehicles, and low-speed electric passenger vehicles. Similar means of transportation have already existed in Europe, the United States, and Japan. Among them, L6e and L7e in EU standard EU-168-2013, neighborhood vehicles stipulated in the US FMVSS 500 regulations, and Japan’s “Ultra-Small Vehicle Certification System” also make detailed regulations and certification systems for ultra-small vehicles.

Low-speed electric vehicles include:

Golf carts and modified carts: used for golf courses, company warehouses to carry goods, construction sites, and home use.

Sightseeing cars, classic cars. For example, it is used in places such as travel at a speed of 20~30km, and security patrols in residential quarters.

Hunting vehicles and off-road vehicles: Due to the characteristics of low-speed and high-torque electric vehicles, the climbing ability is stronger than that of internal combustion engine vehicles.

Special vehicles: such as aerial work vehicles, urban sweepers, garbage trucks, etc.

Police patrol car: the speed is 40km/h, and there are 6 to 20 seats.

Mini electric cars: Most of them are purchased by private individuals and are used for rental, passenger transportation, private cars, etc.

Market problems of low-speed electric vehicles

At present, low-speed electric vehicles still need to deal with many environmental protection issues. Although the state strongly advocates power lithium batteries as the power source of electric vehicles, due to the relatively high battery price, many electric vehicle manufacturers use lead-acid batteries as power sources to obtain higher profits, and the service life of lead-acid batteries is about 2- 3 years, the replacement cycle is short, and the recycling of waste lead batteries is not only costly but also produces lead, sulfur, and other pollutants.

Quality cannot be guaranteed. The state has not yet perfected management methods for low-speed electric vehicles, and no company, large or small, has formed a strict and effective quality control process. Therefore, the quality of many electric vehicles is not guaranteed. When the circuit of the whole vehicle is worn or there is water, there may be a short circuit, which may cause spontaneous combustion, threatening the safety of people’s lives and property.

Traffic orders may be affected. The low-speed electric vehicle market is mainly concentrated in towns and counties. Most of the users are elderly people who do not have driving licenses, and most of the users are not very clear about the traffic rules. When driving low-speed electric vehicles, they often run amok, which seriously affects the traffic order.

The mileage is limited and charging is inconvenient. Low-speed electric vehicles are powered by electricity, and their mileage is generally short. At this stage, my country has not established enough charging facilities. Once the power is exhausted, electric vehicles will not be able to continue driving, which will bring many inconveniences to people’s lives.

Many low-speed electric vehicles do not have a battery management system at all. Therefore, during the use of the vehicle, the battery is not protected from overcharge and over-discharge, resulting in a battery fire accident. Users regard low-speed electric bicycles as electric bicycles with “sheds”, which are too casual when charging and using, and lack necessary maintenance.

Common low-speed vehicle batteries

An important key to the development of electric vehicles is the improvement of battery energy storage capacity. To support the energy required by the electric vehicle motor, the battery itself must be able to provide high current output for a long time and increase the instantaneous high current output, and the number of charging times and charging time of the battery itself needs to meet the demand, and it is necessary to ensure that the battery It will not endanger the safety of vehicles and people under the influence of collision, puncture or even bad weather. In addition, it is also necessary to consider that the material composition of the battery will not cause damage to the environment and ecology in the future. Therefore, whether electric vehicles can truly replace current gasoline vehicles, in addition to motor drive technology, also depends on whether there is a breakthrough in battery technology. The types of batteries currently used in electric vehicles need to consider the following factors:

Security

Recharge time

Energy supply

Ambient temperature

Battery performance limit

Environmental issues

Life problems

At present, the well-known types of batteries are lead-acid batteries, nickel-cadmium batteries, nickel-hydrogen batteries, and lithium-ion batteries, but no matter what kind of batteries, they all use electrochemical reactions to achieve energy storage and release.

Lead-acid batteries:

The lead-acid battery is the earliest developed and most mature battery, so the manufacturing cost is relatively low, and it has the characteristics of strong instantaneous discharge capacity and a wide operating temperature range. However, lead-acid batteries do not perform well in energy density, cycle life, and other performance, and there are environmental problems at the same time.

Nickel-cadmium batteries:

Compared with lead-acid batteries, nickel-cadmium batteries have higher energy density and lifespan, and can also be charged and discharged at large currents. They are also highly adaptable to overcharge and over-discharge, but because of their memory effect and strong material toxicity, they will cause serious pollution to the environment and have been banned by many countries.

NiMH batteries:

The NiMH battery itself does not contain heavy metals (lead, and cadmium) that are harmful to the human body. The charging and discharging times are high, and the discharge depth and the service life are good, but there are still the shortcomings of memory effect and slow charging rate.

Lithium-Ion Battery:

Lithium-ion batteries can be divided into many types, mainly due to the difference in the positive electrode materials used, which can be divided into LiCoO2, ternary battery LiMn2O4, and lithium iron phosphate battery. Among them, in the low-speed vehicle market, LiMn2O4 and lithium iron phosphate batteries are the most common, while in the General Electric car market, ternary batteries and lithium iron phosphate batteries are the main ones.

Comparison of characteristics of common battery products for low-speed vehicles:

| Battery Type | Lead-acid batteries | Nickel-cadmium batteries | NiMH batteries | Lithium manganese battery | Lithium iron phosphate battery |

| Operating Voltage (V) | 2 | 1.2 | 1.2 | 3.7 | 3.2 |

| The volume energy density (Wh/L) | 100 | 150 | 250 | 285 | 275 |

| The gravimetric energy density (Wh/Kg) | 30 | 60 | 80 | 110 | 145 |

| power (W/Kg) | 300 | 150 | 800 | 400 | 2000 |

| safety | good | good | good | ordinary | excellent |

| charging time | long | short | medium | medium | short |

| Energy Efficiency (%) | 60 | 75 | 70 | 90 | 95 |

| memory effect | none | a lot | little | none | none |

| cycle life | 400 | 500 | 500 | 800 | >2000 |

| Environmental issues | exist | exist | none | none | none |

Advantages of lithium iron phosphate batteries

The lithium iron phosphate battery (LiFePO4) itself has a low raw material price, and the resource content of phosphorus, lithium, iron, and other elements is rich, and there is no feeding problem. At the same time, the lithium iron phosphate has an olivine structure, with a stable structure, both environmental protection and safety. There is no danger of explosion.

On the whole, since the advent of lithium batteries, its related research and development work has been carried out continuously, and it has gradually replaced lead-acid batteries and nickel-metal hydride batteries as the mainstream rechargeable batteries. At the same time, lithium iron phosphate batteries are one of the most likely to become the mainstream development of electric vehicles because of their safety, high current charge and discharge, and long cycle life.

The comprehensive advantages of lithium iron phosphate are as follows:

Moderate and stable working voltage: its working voltage is 3.2V, which is slightly higher than other batteries, and has a high and stable voltage comparable to that of general voltage regulators.

High discharge power: suitable for large power batteries that require high power, especially for vehicle batteries.

Good electrochemical performance: fast charging and cycle life of more than 2000.

Ambient temperature: high temperature and high thermal stability are much higher than other cathode materials.

Energy conversion efficiency: The conversion efficiency of lithium iron phosphate can reach 95%, much higher than 60% of lead-acid batteries and 70% of nickel-metal hydride batteries.

Good safety performance: It can pass puncture and collision tests without explosion.

Green environmental protection: It is harmless to the ecological environment and belongs to the environmental protection green material.

Considering that during the driving process of electric vehicles, in the event of a traffic accident, the in-vehicle battery may be subject to hazards such as extrusion, collision, and puncture. Therefore, in addition to good electrochemical performance, the safety of the battery itself is also extremely important. At present, the performance of lithium iron phosphate batteries in safety tests and the actual loading experience are satisfactory. It is foreseeable that more and more low-speed electric vehicles will replace traditional gasoline vehicles in the future, and lithium iron phosphate batteries will also play an important role.